Explore Products

Products

Couplings

Geislinger Coupling

Robust torsional elastic, high- damping steel spring coupling. The Geislinger Coupling is a torsional elastic high-damping steel spring coupling with hydrodynamic damping properties. High reliability, long intervals between overhauls, and low operating costs are some of the main features of this ATEX-certified coupling. While steel leaf springs transfer torque and provide elasticity, pressured oil ensures high hydrodynamic damping. The Geislinger Coupling is perfectly suited for all types of drivetrains where outstanding reliability is essential.Applications: Marine, Power Generation, Off-Highway, Wind Power & Renewables, Industrial Applications, Digital Solutions.

see more at geislinger.com

Couplings

Geislinger GESILCO® BUTTERFLY

The world’s most lightweight misalignment coupling. The Geislinger GESILCO® Butterfly is a misalignment coupling made from lightweight and highly flexible advanced composite material membranes. This achieves the lowest reaction force possible, which increases the system’s reliability by protecting the driveline and bearings from possible overloads. This unique coupling is suitable for a wide range of applications. Its multiple designs make it compatible with a variety of connection interfaces. Applications: Marine, Power Generation, Off-Highway, Wind Power & Renewables, Industrial Applications, Digital Solutions.

see more at geislinger.com

Couplings

GEISLINGER SAE Coupling

Compact, torsional elastic steel spring coupling for SAE standards. The Geislinger SAE Coupling is the perfect solution for installations in harsh environments with tight installation spaces, low

air ventilation, and high air temperatures. It complies with SAE standards and is ATEXcertified. Available in four different stiffness levels, the Geislinger SAE Coupling adapts perfectly to the stiffness and torque requirements of different applications. Applications: Marine, Power Generation, Off-Highway, Industrial Applications, Digital Solutions.

Couplings

GEISLINGER SILENCO®

Lightweight composite coupling with highest acoustic sound attenuation. The Geislinger SILENCO® Coupling is an acoustically optimized misalignment coupling. It consists of flanges, long service life composite membranes with increased damping properties, composite shafts, and steel spacers. The coupling provides superior chemical resistance, and it is electrically insulated. Depending on the acoustical needs and the required torque, different versions of flanges, membranes, and shafts are available. Applications: Marine, Off-Highway, Wind Power & Renewables, Industrial Applications, Digital Solutions.

see more at geislinger.com

Couplings

Geislinger CARBOTORQ®

Lightweight, torsional elastic misalignment coupling. The CARBOTORQ® is a lightweight, elastomer coupling that combines advanced composite material and silicone elastomer. It is designed to minimize reaction forces and bearing loads while providing torsional elasticity and misalignment capacities with the lowest possible weight. The torsional elastic component is bonded between fiber composite membranes, which provide elasticity and high internal damping properties. Applications: Marine, Power Generation, Industrial Applications.

see more at geislinger.com

Couplings

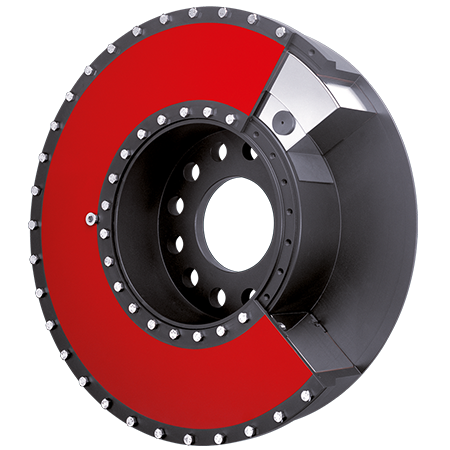

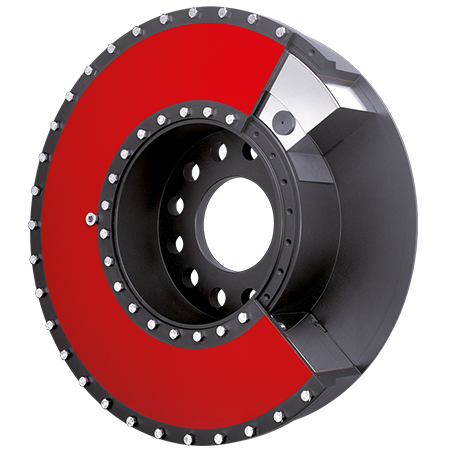

Geislinger GESILCO® DISC

Lightweight, electrically insulating coupling solution. The GESILCO® Disc coupling became the new industry standard for close coupled gensets in high-performance applications like rail or mining. The coupling is designed using advanced materials and is specifically developed for closed coupled generator sets and highly integrated wind turbine powertrains. Under extreme and rough conditions, the highest shock resistance of the GESILCO® Disc coupling as well as its homokinetic, nonmagnetic and non-conductive properties are an essential benefit. Applications: Marine, Wind Power & Renewables, Power Generation, Off-Highway, Industrial Applications, Digital Solutions.

see more at geislinger.com

Couplings

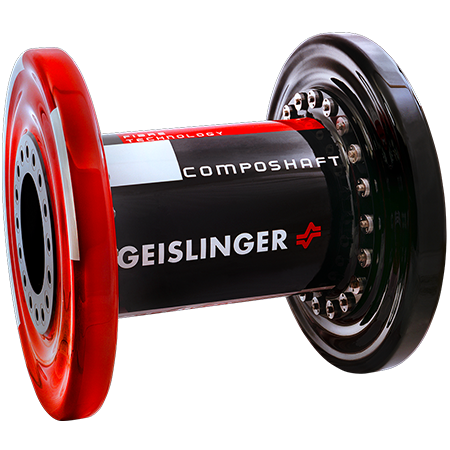

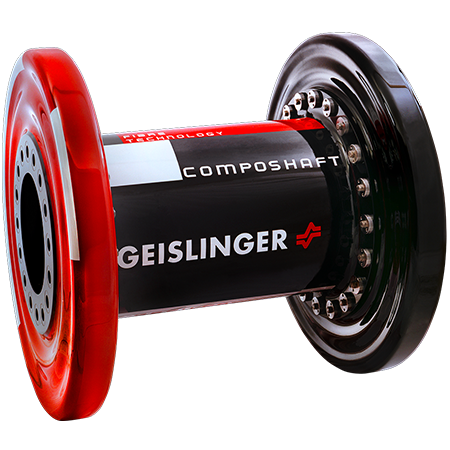

Geislinger GESILCO® COMPOSHAFT

Lightweight, advanced composite material coupling. The COMPOSHAFT® misalignment coupling consists of two double membranes and an intermediate shaft made of advanced composite materials. The membranes are corrugated with decreasing wall thickness, as the diameter increases. The superior advantages of the corrugated membrane design, in comparison to a flat

membrane, are a higher deflection capacity and lower, almost linear reaction forces. Applications: Marine, Power Generation, Off-Highway, Industrial Applications, Wind Power & Renewables, Digital Solutions.

Couplings

GEISLINGER FLEXLINK

Heavy duty, robust, misalignment steel coupling. The Geislinger Flexlink is a misalignment coupling specifically designed for heavyduty applications. Even with maximum misalignments in axial-, radial-, and angular directions, the Geislinger Flexlink reduces the reaction forces to a minimum. This lowers the bearing loads and helps to avoid torsional excitations, which in turn

extends the service life of the drivetrain. Its high permissible torques and its resistance to heat and oil make it a solution for numerous applications – particularly if long service life and reliability are critical requirements. Applications: Marine, Power Generation, Off-Highway, Industrial Applications, Digital Solutions.

Couplings

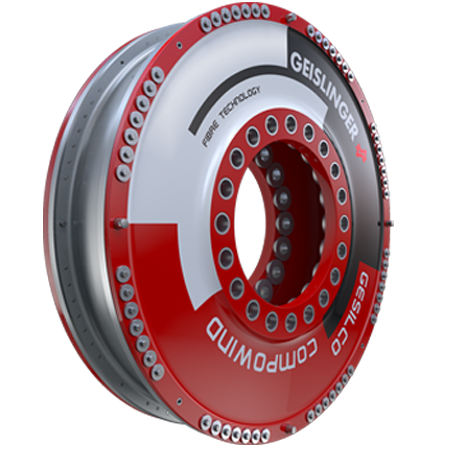

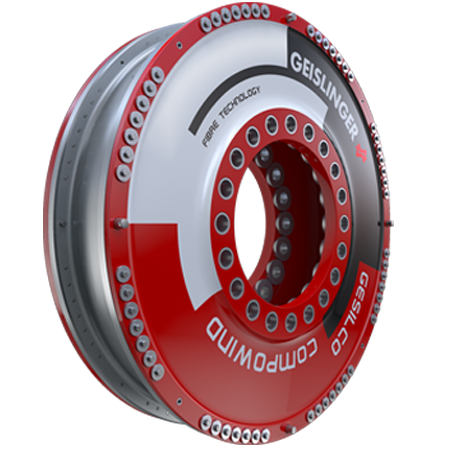

GEISLINGER COMPOWIND® COUPLING

Fatigue-resistant, high protective composite coupling. Installed between the rotor hub and the gearbox, the low-speed shaft (LSS) coupling protects the gearbox and the whole drivetrain by significantly reducing nontorque loads. The coupling design allows the gearbox to be mounted rigidly onto the main frame without the use of elastomer-hydraulic torque supports. As a result,

bending modes and dynamic effects are virtually eliminated. The reliability of the drivetrain increases noticeably, resulting in reduced operational costs. Applications: Wind Power & Renewables.

Couplings

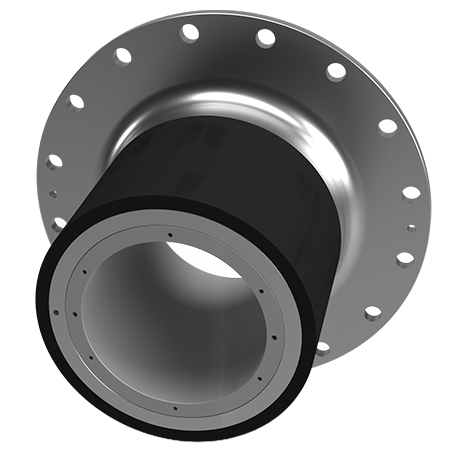

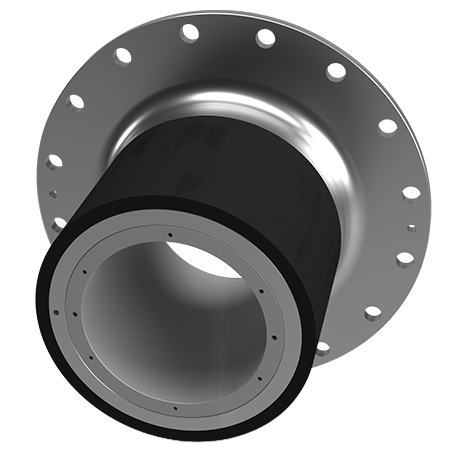

Geislinger Hub

Lightweight, fiber-reinforced composite shaft coupling. The use of fiber-reinforced composite shafts is a major benefit for lightweight powertrains due to their low mass. The innovative Geislinger Hub connects a cylindrical solid shaft by means of a bolted flange and helps to further reduce the weight of the whole driveline. Compared to conventional hub designs, the Geislinger Hub also facilitates the design of shaftlines that are much more compact due to higher torque transmission within the same installation space. Applications: Marine, Power Generation, Industrial Applications.

see more at geislinger.com

Dampers

Geislinger Vdamp®

Torsional vibration viscous damper with broadband effect. The Geislinger VDAMP® and VDAMP®XT are tailor-made viscous dampers that protect engine camshafts and crankshafts

from possible damage caused by torsional vibrations, and help to avoid barred speed ranges. The vibration energy is converted into heat, which then dissipates from the damper’s surface into the ambient air. Due to the innovative Geislinger calculation method, the viscous damper can be perfectly fitted to any individual application. Applications: Marine, Power Generation,

Off-Highway, Industrial Applications, Wind Power & Renewables.

Dampers

GEISLINGER DAMPER

Tuned, torsional vibration steel spring damper. The tailor-made Geislinger Damper is specifically designed for applications, where high performance, the most compact design, and low cost of ownership is requested. The steel springs optimize the natural frequency of a system to significantly reduce the critical resonances. The Geislinger Damper is a tuned torsional vibration damper providing constant stiffness and excellent damping throughout its service life. Applications: Marine, Power Generation, Off-Highway, Industrial Applications, Wind Power & Renewables.

see more at geislinger.com

Shafts

Geislinger GESILCO® SHAFT

Lightweight, advanced composite shaft solution. The GESILCO® shaftlines are made of advanced composite material and are characterized by their innovative one-piece manufacturing

with a unique integrated fiber flange connection. The GESILCO® shafts can easily be adapted to your requirements including bearings, bulkhead seals, and GESILCO® composite misalignment

couplings. Outstanding shock capabilities underline the use of Geislinger shafts for vessels running at high speeds. Applications: Marine, Wind Power & Renewables, Power Generation, Off-Highway, Industrial Applications.

Shafts

Geislinger GESILCO® Silentshaft

Acoustically optimized, torsional elastic and vibration damping shaft solution. The Geislinger GESILCO® Silentshaft is made of advanced composite materials, and is characterized by excellent torsional stiffness characteristics and an unique integrated fiber flange connection. The Geislinger GESILCO® Silentshaft Coupling isolates the drivetrain system from vibrations and is our solution for mitigating noise, vibration, and harshness for onshore wind turbines. It is tailor-made and can easily be adapted to any requirements. Applications: Wind Power & Renewables.

see more at geislinger.com

Monitoring

Geislinger Monitoring System Mk6

The latest Geislinger Monitoring System (GMS) Mk6 is based on 30 years of experience in torsional vibration monitoring and is the gateway to the digital world. It is a continuous monitoring and measuring system for Geislinger dampers, couplings, and shaftlines. Connectivity and data acquisition in the new GMS Mk6 enable Big Data analysis and machine learning. This data can

be used for further system analysis or condition monitoring using machine learning or statistical analysis combined with expert knowledge. Applications: Marine, Wind Power & Renewables, Electric & Hybrid, Power Generation, Industrial Applications, Off-Highway, Testing & Development.

Monitoring

Geislinger Analytics Platform

Cloud-based online monitoring platform for torsional vibrations & continuous measurements. Monitoring your drivetrain with Geislinger Digital Solutions enables multiple features such as trend analysis, AI-powered anomaly detection, rapid troubleshooting, data analytics, reporting, predictive maintenance, and much more. Our solution also ensures maximum safety, prevents

downtime, mitigates overall operational risk, and provides a solid foundation for fuel savings and ultimately a reduction in CO2 emissions, helping you to future-proof your application. Applications: Marine, Wind Power & Renewables, Electric & Hybrid, Power Generation, Industrial Applications, Off-Highway, Testing & Development.